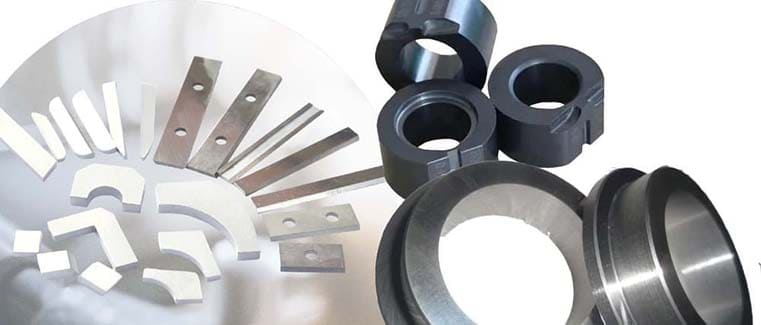

At Tungsten C Tools, we provide precision-engineered carbide components built to withstand abrasive rock, extreme pressure, and high-impact operations. Our custom solutions ensure longer tool life, reduced downtime, and maximum productivity in the toughest mining environments.

• Carbide Drill Bits

Used in rotary and percussion drilling for hard rock formations.

• Carbide Tipped Rock Drill Inserts

Enhance penetration efficiency in tough mining conditions

• PDC (Polycrystalline Diamond Compact) Cutters

Used in high-performance drill bits for deep mining

• Carbide Mining

Picks

Installed on

continuous miners and roadheaders for cutting coal and rock.

• Carbide-Tipped

Conical and Shearer Picks

Used in coal

mining machines for high-efficiency cutting.

• Crushing and

Pulverizing Tools

• Carbide Wear

Plates & Liners

Used in chutes,

hoppers, and conveyor systems to extend service life.

• Carbide Bushings

& Nozzles

• Carbide Button

Inserts

Used in TBM disc

cutters for boring through hard rock.

• Carbide Shield

Cutter Heads

With more than three decades of specialized experience, we deliver precision tungsten carbide components engineered to perform in the world’s most demanding equipment & manufacturing applications

Backed by internationally recognized quality management and environmental standards, we ensure consistent product quality and sustainable manufacturing practices.

Precision engineering solutions, designed to meet the operational demands and performance challenges of the mining sector, with exceptional durability and efficiency.